핵심 기술

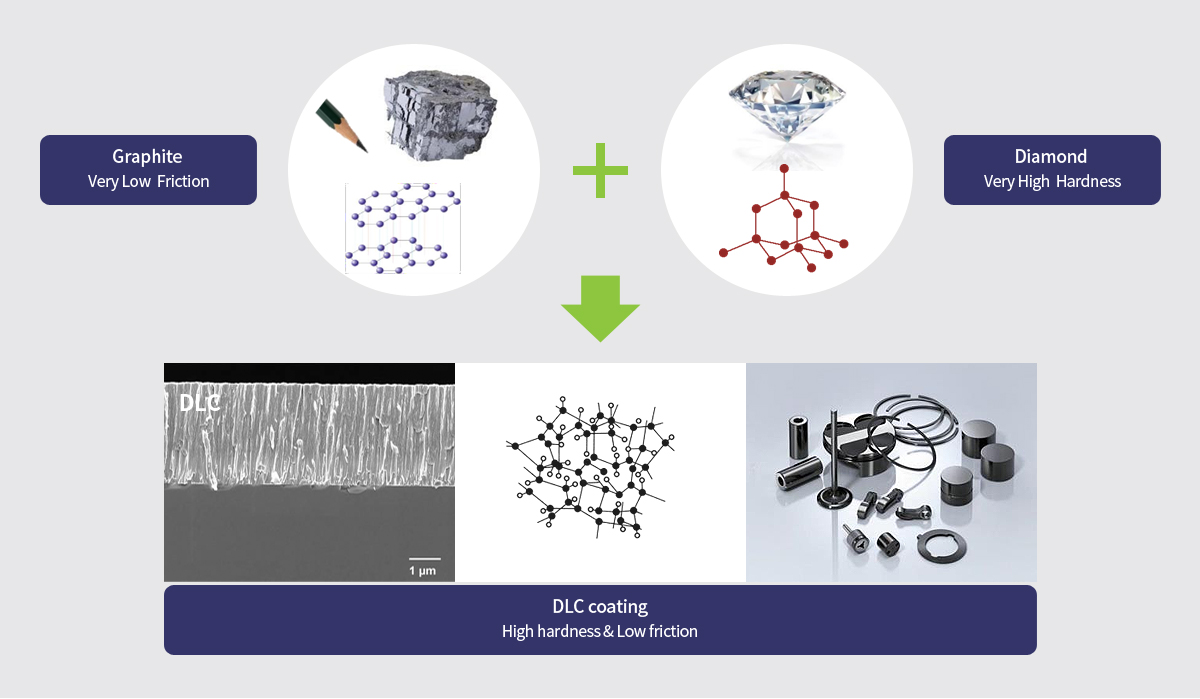

Why DLC coating ?

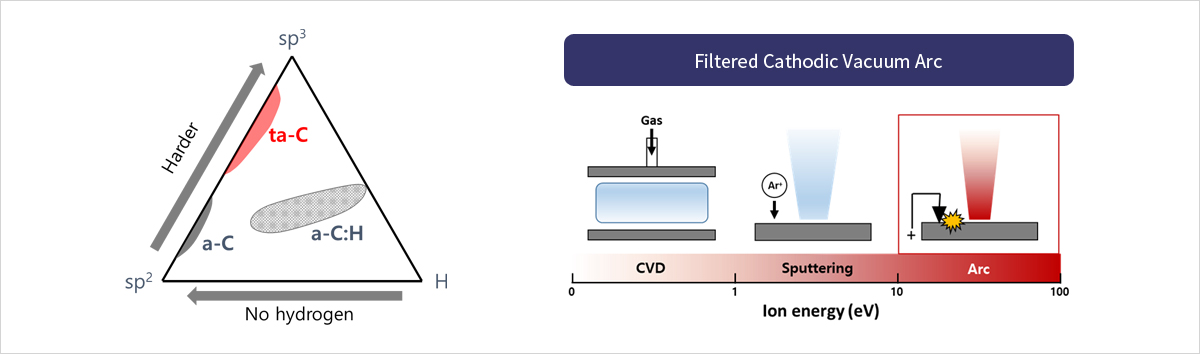

Diamond-Like Carbon (DLC) coating

HF-DLC coating (FCVA)

| 1st generation |

2nd generation |

3rd generation |

|

|---|---|---|---|

| Method | CVD | Sputter | Arc |

| Classification | Hydrogen-containing Carbon amorphous | Non hydrogen Carbon amorphous | Non hydrogen Diamond-containing amorphous |

| Ionization rate | 10% | 5-30 % | 90% |

| Hardness (GPa) | < 10 | < 20 | > 30 |

| Heat resistance (℃) | < 350 | < 350 | < 500 |

-

Coating bar -

Cutting tool -

Injection mold -

Engine component

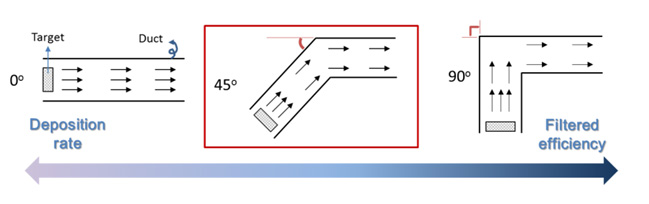

Why FCVA deposition?

FCVA (Filtered Cathodic Vacuum Arc) deposition

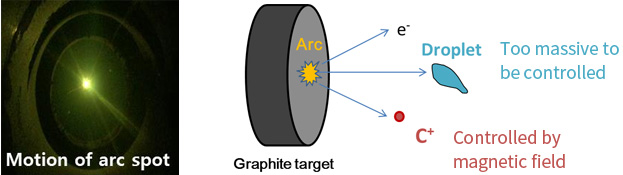

VA (Vacuum Arc)

High kinetic energy (10-30 eV)  Graphite fragment (droplet)

Graphite fragment (droplet)

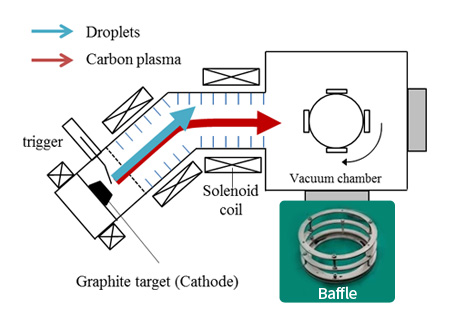

FCVA (Filtered Cathodic V.A.)

To prevent inflow of droplet,

a magnetic field, curved duct

& filter are introduced  Inflow of macro-particles were inevitable

Inflow of macro-particles were inevitable

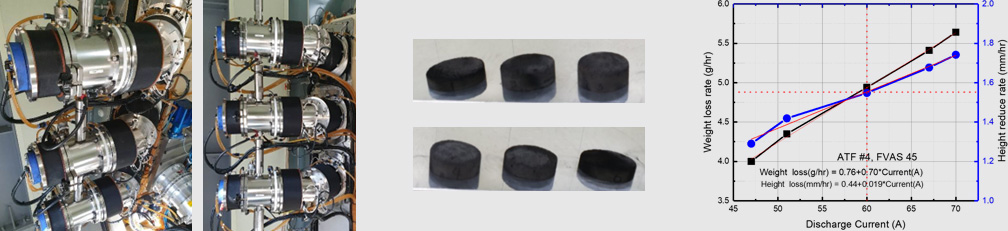

System Scale up

Scale up _ Long Sample

Cathode Life Time

: Φ50 x 40L

1.8mm/hr. @70A

= 15 hr

Target Height loss(mm/hr) = 0.44+0.019*Current(A)

공동개발 및 기술이전

한국재료연구원 표면재료연구본부 극한환경코팅 연구실 트라이볼로지 코팅팀 Tribology Coationg Lab., Department of Extreme Environmental Coationgs Surface Materials Division,

Korea Institute of Materials Science (  )

)